-

-

Bogie-hearth Blast Air Oven

This bogie-hearth blast air oven is mainly used for drying acrylic paint parts, paint, cabinets, soaking insulation Paint transformers, motors, welding electrodes, powdery or granular plastic raw materials, sand-casting, one-time paper cups, bowls, food, timber logs, wood products, such signs....

Tags: Raceway Blast Air Oven | Drying Sintering Oven | Box Type Glass Melting Oven | Box Type Organic Drying Oven

Description

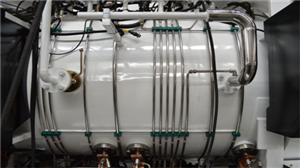

Anti-oxidation coating furnace has deposition chamber and evaporation chamber, which putting the matrix material (Graphite or C/C) into the deposition chamber, then putting precursor (NaCI, ZrCI4) into the evaporation chamber. The precursor will evaporate under heating in the chamber, the vapor will go into the deposition chamber through high temperature pipeline, then the precursor material will deposition on the matrix surface to form a coating to improve the anti-oxidation.

Technical Features

1. Vacuum coating furnaces have top and bottom two chambers, which has separate deposition temperature and evaporation temperature control zone.

2. The coating speed and time is controlled by controlling the evaporation temperature. it can also add precision powder deliver device on the evaporation chamber to input certain precursor to control the deposition speed and time.

3. The special high temperature connecting technology is adopted to make the precursor vapor without condense and jam.

4. The special designed high temperature infrared measurement technology is adopted with precision temperature control and close error.

5. The furnace uses special exhaust gas treatment device, which is friendly to environment and convenient for cleaning.

Optional Configuration of Anti-oxidation Coating Furnace

1. Furnace door: hinge turning type/ trolley type, manual tight/auto lock-ring tight

2. Furnace vessel: All carbon steel/Inner layer stainless steel/Total stainless steel

3. Furnace hot zone: Soft carbon felt/Soft graphite felt/Hard composite felt /CFC

4. Heating element and muffle: Isostatic press graphite/Press high purity, high strength and high density graphite/ fine size graphite

6. Vacuum pump and gauge: foreign brand/Chinese brand

7. PLC: OMRON/Siemens

8. Temperature controller: SHIMADEN/EUROTHERM

9. Thermocouple: C type, S type, K type, N type

10. Recorder: Paperless recorder/paper recorder, foreign brand/Chinese brand

12. Infrared meter: Single color/double color, CHINO/Raytek

13. HMI: Simulation screen/Touch screen/Industrial personal computer

14. Electric components: CHINT/Schneider/Siemens

15. Load truck: roller type /Fork type/Folded long distance driving type