-

-

Bogie-hearth Blast Air Oven

This bogie-hearth blast air oven is mainly used for drying acrylic paint parts, paint, cabinets, soaking insulation Paint transformers, motors, welding electrodes, powdery or granular plastic raw materials, sand-casting, one-time paper cups, bowls, food, timber logs, wood products, such signs....

Tags: Raceway Blast Air Oven | Drying Sintering Oven | Box Type Glass Melting Oven | Box Type Organic Drying Oven

Description

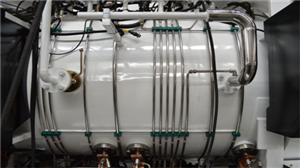

Vertical vacuum water quenching furnace is applied for the solution of titanium alloy in aerospace industry, such as TC4, TC16, beryllium bronze in aircraft instrument elastic elements. Precision alloy in aircraft sensor like Ni-based and Co-based high elastic alloy 3J1, 3J21, Ni-based constant elastic alloy 3J53, stainless steel in the field of nuclear energy like17-4PH, 410.

Technical Features

1. The furnace is vertical and twin chamber structure. Integral type or split type structure are optional in accordance with site situation.

2. Jobs loading type: handing type or bracket type.

3. The furnace hearth is designed through modularized optimization with good temperature uniformity performance.

4. Vertical vacuum water quenching furnace has extendibility, which can improves the production efficiency.

5. Compared with horizontal transmission quenching device, the quenching device made up of vertical material lifting trolley, which has the advantage of shorter transportation time.

6. There is no need to charge other gases to suppress water vapor entering into heating chamber and polluting the vacuum pump system.

7. Vertical water quenching furnace is equipped with cooling circulation system with high volume water quenching tank, which has a better water quenching effect.

8. The water vapor has no any pollution to the heating chamber and pumps.

Optional Configuration of Vertical Vacuum Water Quenching Furnace

1. Twin chamber vertical structure: integral type/movable heating chamber type/movable water tank type

2. Furnace hearth: molybdenum heating elements and metal heat insulation

3. Quenching water stirring type: paddle stirring/nozzle stirring/both of the two types

4. Vacuum pump and gauge: foreign brand/high-quality Chinese brand

5. PLC: OMRON/Siemens/Mitsubishi

6. Temperature controller: SHIMADEN/EUROTHERM/Honeywell

7. Thermocouple: S type, K type, N type

8. Recorder: Paperless recorder/paper recorder

9. HMI: Simulation screen/Touch screen

10. Electric components: High-quality domestic brand/Schneider/Siemens